Experiencing engine malfunctions can be a challenging ordeal for drivers as it disrupts the operation of car accessories. Are you curious about Volvo D12 engine problems? This post offers a detailed exploration of each issue’s causes and provides comprehensive solutions. Follow us to uncover the answers you seek!

Decoding the Volvo D12 Engine

The Volvo D12 engine marked a groundbreaking moment in 1993. Göran Nyholm, a retired Volvo engineer, shares the story behind this remarkable engine’s inception. Introduced in an FH Volvo truck, the D12 engine heralded the dawn of a new generation of trucks. Journalists from around the globe attended the unveiling, and Volvo’s advancements were met with awe. Ahead of its time, Volvo integrated an engine brake, electronic steering, and improved cylinder head quality, anticipating and exceeding emission standards. The road to success wasn’t without challenges. Collaborating with Cummins engineers in the US, Volvo overcame obstacles to create the ideal cylinder head and electronic steering system, giving birth to the D12 engine.

Today, the D12 Volvo engine remains a dependable powerhouse. Known for reliability, safety, fuel efficiency, and impressive performance, it has evolved through four generations: D12A, D12B, D12C, and D12D. Each iteration boasts increased torque and horsepower, coupled with minor mechanical and electrical tweaks. Designed for heavy-duty applications, the D12 engine meets industry demands with its electronic fuel injector, four valves per cylinder, and single overhead cam configuration. Featuring an excellent charge-air cooler for temperature regulation and reduced emissions, it adheres to stringent UK, US, and EU standards. The D12 engine’s substantial torque ensures smooth acceleration even under heavy loads. Additionally, its low-speed option allows engine speed reduction by half.

Renowned for its reliability, the Volvo D12 engine is widely used in various vehicles, including Mack trucks like Mack CH and Mack Vision, Prevost coaches like Prevost X3-45 and Prevost H3-45, and Volvo trucks such as Volvo FM, Volvo VN, Volvo FH, and Volvo Penta. Newer Prevost models now adopt the D13 Volvo engine.

Minimizing Volvo D12 Engine Problems: Expert Tips

If you find your D12 engine’s accessory drive failing more frequently than expected, avoid merely changing it repeatedly. Instead, focus on this crucial step: inspect the accessory drive bracket. Tightened with a long bolt, the bracket features a locking pin at the rear end. A faulty locking pin can lead to upward movement, disrupting the drive belt rotation and causing it to rub against other pulleys.

- To address this issue effectively, replace the bracket and thoroughly examine the upper place where the accessory drive tightens. In some cases, changing both the bracket and the front engine cover might be necessary for a lasting fix. This comprehensive approach will not only resolve the accessory drive problem but also tackle any associated oil issues from the cover;

- Preventing overheating is paramount for your D12 engine’s health. Always ensure the radiator is filled with the recommended coolant and stays within the designated fill mark. Additionally, maintain the cooling system’s other components in optimal condition to prevent overheating concerns;

- Avoid placing excess load on the engine to steer clear of fuel pressure issues. If you notice any malfunction with the fuel pump, promptly replace it. Addressing potential problems before they escalate will contribute to the engine’s longevity and performance;

- Lastly, if your truck experiences starting issues, diligently identify and rectify the root cause. Numerous factors can hinder engine ignition, so a thorough investigation is essential to resolve the problem promptly.

Exploring Common Problems of the Volvo D12 Engine

The Volvo D12 engine is renowned for its strength and reliability, making it a popular choice for various truck manufacturers. However, like any complex system, it’s not without its flaws. Let’s delve into some of the common issues that you might encounter with this engine.

One prevalent problem faced by the D12 Volvo engine is overheating. Several factors, such as a faulty radiator, coolant leakage, clogged coolant passages, or a defective water pump, can contribute to this issue. If you notice the temperature gauge creeping into the red zone or see steam emanating from under the hood, it’s likely your engine is overheating.

While not widespread, fuel pressure problems can occasionally arise in D12 engines, particularly under excessive engine stress. A weak fuel pump could be the underlying cause of this issue.

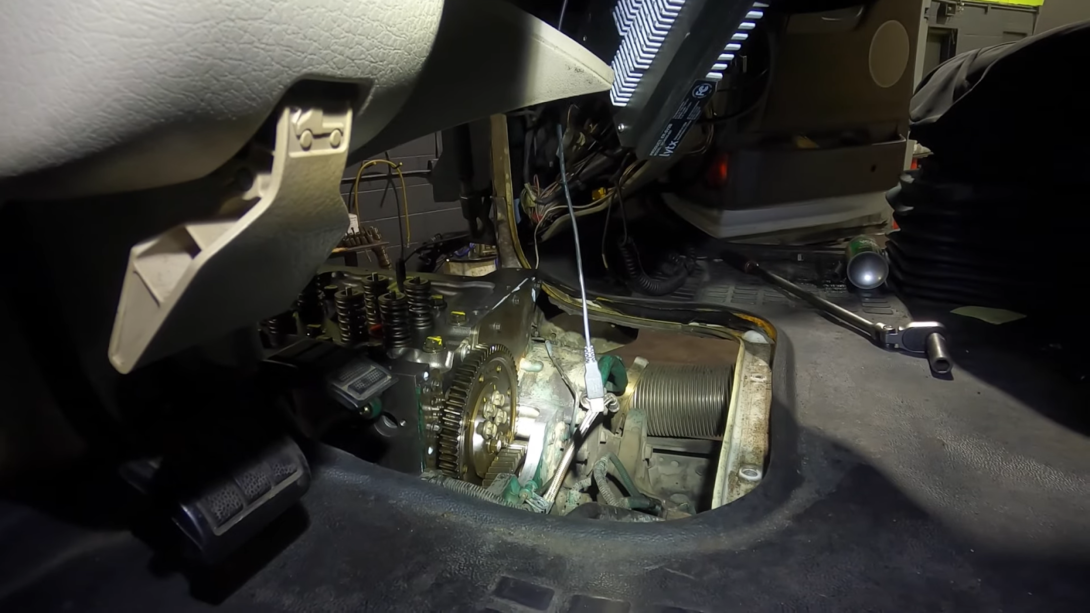

Another common concern is a faulty accessory driver, also known as the idler pulley. Some Volvo D12 marine engines have experienced problems with these idlers, leading to the need for replacements over time. Some mechanics and drivers have reported that the accessory drive fails again after just two to three months, attributing the frequent failure to the pin on the accessory drive.

Lastly, oil leakage is another prevalent D12 engine problem. Drivers often complain of oil leaks from the front of the engine, especially when the accessory driver malfunctions. However, fear not, as solutions for rectifying this issue will be discussed in the following paragraphs.

Causes of Volvo D12 engines not starting

Trucks, including Volvo models, may encounter starting problems from time to time. Both the D12 engines are susceptible to this issue, with several potential causes. Some reasons are unique to these specific engines, while others can affect any truck engine. Let’s explore the common causes behind starting difficulties:

Battery Problems

The key to a successful truck start lies in a well-maintained battery. Often, when your truck encounters starting issues, a faulty battery is the prime suspect. Responsible for powering your Volvo truck’s control and consumer units, the battery’s condition is crucial.

Keep in mind that a car battery’s capability diminishes over time. Its charging capacity gradually reduces, leading to insufficient power to start the truck eventually. Most batteries have a limited lifespan, with manufacturers recommending replacement every five years.

Diagnosing and Addressing Starter Problems

Diagnosing and addressing battery problems is essential for smooth engine starts. If you hear a ‘click’ sound upon ignition or notice dashboard lights fading or flickering, it could indicate a failed battery that needs replacement.

Occasionally, starting issues may arise due to a bad connection in the battery master disconnect switch, located on the frame above the batteries. Simply tightening the cables at the back can resolve this and ensure the batteries power the engine effectively.

To maintain the batteries’ full charge and extend their life, regular charging using an integrated top charger is recommended. Additionally, during winter or periods of non-use, turn off consumer instruments like the radio to preserve battery power.

Alternator problems

The alternator plays a crucial role in keeping your truck’s engine operational. Its primary function is to regulate and supply electrical power to the truck’s electrical system, ensuring all components, including the engine, receive the necessary energy. Several telltale signs indicate a faulty alternator:

- Dead battery: A drained battery, despite recent charging, may suggest alternator problems;

- Engine not starting and frequent stalling: A malfunctioning alternator can lead to engine starting issues and unexpected stalls while driving;

- Overly bright or dim lights: Inconsistent lighting intensity may signify irregular electrical power supply from the alternator;

- Battery warning light: If the battery warning light illuminates on the dashboard, it could indicate alternator trouble;

- Slow or malfunctioning accessories: Sluggish or malfunctioning electrical accessories like the radio or power windows might result from alternator issues.

Diagnosing and Addressing Starter Problems

Given the critical role of the alternator in powering your truck, addressing any problems promptly is essential. If you suspect alternator misbehavior, seek professional assistance immediately to prevent potential breakdowns in remote locations. A mechanic can perform testing or replacement using a charging system analyzer to confirm the alternator’s functionality.

Ignition switch

Whether you use keys or the ‘push’ button as ignition keys to your Volvo truck, you need to beware that ignition uses electrical power from the energy. If the ignition has an issue, the truck will not start. The ignition key works together with the ignition lock cylinder, and you should check both when diagnosing a starter switch problem.

Besides the ignition switch making the engine fail to start, it can cause your truck to stall, posing a serious risk to yourself and other road users.

Diagnosing and Fixing Wiring Problems

The first thing to check when you suspect you have an ignition switch issue is the battery. Confirm whether the battery is in good condition and whether it is supplying enough output charge. If the battery is okay, an expert should check the system to establish where the problem lies. The mechanic can also know whether any wiring problems are causing the ignition not to work.

Starter problems

Similar to the ignition switch, the starter relies on the battery’s power to function. Before delving into fixing the starter, ensure the battery is in optimal charging and efficient condition. The starter comprises various components, such as the solenoid, brushes, lever fork, and pinion coils. Any damage to these parts can result in your D12 engine failing to start.

Diagnosing and Addressing Starter Problems

Identifying the exact component responsible for the faulty starter can be challenging. However, a digital multimeter proves invaluable in determining the starter’s condition. Consult the user manual for detailed instructions on how to test the starter, including measuring points specified in the D12 service manuals.

To begin the testing process, unplug the starter relay and utilize the digital multimeter to conduct the assessment. Following the provided guidelines, you can accurately diagnose the starter’s functionality and identify any issues that require attention.

Wiring

After driving your truck for extensive miles, wear and tear on the wiring system can occur, making it challenging to trace and identify issues. Faulty wiring may disrupt communication and transmission, preventing your truck from starting. In some instances, truck drivers may attempt to crank their trucks, only to find that the dash lights up, but the truck refuses to start.

When faced with such a problem, it is advisable to seek the expertise of a Volvo truck specialist. They possess the knowledge and tools to diagnose and resolve wiring problems effectively.

Diagnosing and Fixing Wiring Problems

In online forums, some Volvo D12 truck owners have shared their experiences with similar issues. They discovered that fused wires affecting the electronic control unit’s (ECU) communication capabilities were the cause of their troubles.

Others found that a severely corroded fuse box was the culprit. Upon replacing it, their trucks started flawlessly, and they encountered no further problems. While tracing the wiring system can be tedious, it is essential to check the truck’s wiring after confirming that critical components like the starter and alternator are functioning correctly.

Fuel problems

An engine deprived of fuel will not start or run smoothly. In some cases, the truck may struggle to start or exhibit rough idling. Additionally, the engine may run lean due to insufficient fuel supply. The root of this fuel issue can be traced to various components, such as a clogged fuel system, fuel filters, or a malfunctioning fuel pump.

Diagnosing and Addressing Fuel Problems

Neglecting the D12 engines and allowing fuel to pass through worn and damaged filters can lead to severe engine problems. Debris can infiltrate the engine, causing a range of issues, including starting difficulties. To rectify this, promptly replace any worn fuel filters.

To diagnose fuel-related problems comprehensively, run a diagnostic test on the truck. This will help identify potential issues with the fuel injector or the fuel tank. If the diagnostic codes indicate problems with the fuel tank, it is advisable to replace the EVAP canister and clean the hose connected to the EVAP system. Cleaning the fuel tank is also essential to remove all dirt and residue.

Conclusion

In conclusion, addressing the common issues faced by the Volvo D12 engine is vital for maintaining its reliability and performance. From diagnosing battery, alternator, and starter problems to resolving fuel-related issues and tracing wiring problems, proactive maintenance and timely fixes are key. By adhering to proper troubleshooting techniques and seeking expert assistance when needed, owners can ensure their Volvo D12 engines continue to power trucks smoothly and efficiently, offering a seamless driving experience on the roads.