Universal joints, commonly referred to as U-joints, are critical components in a vehicle’s drivetrain, ensuring a smooth transfer of power from the engine to the wheels. Understanding the function of U-joints, how to maintain them, and troubleshooting common issues can help you keep your vehicle running smoothly and safely. This article will provide a comprehensive overview of U-joints, including their types, maintenance procedures, and potential problems.

The Function of U-Joints

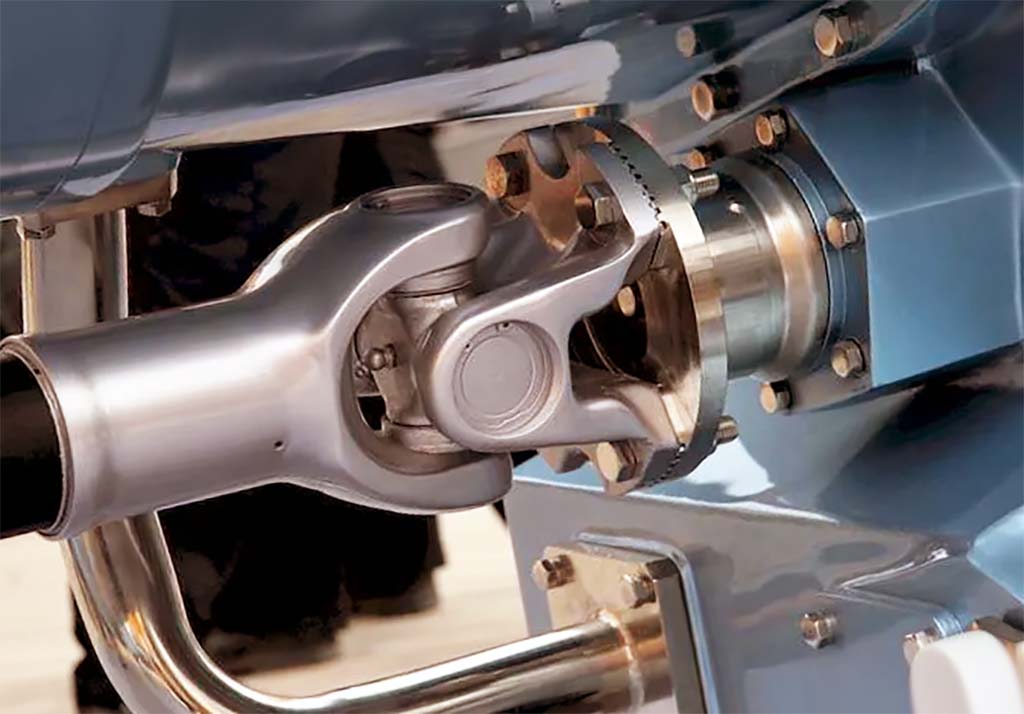

U-joints are flexible couplings that allow for the transmission of torque between two shafts at varying angles. They are typically found in the driveshaft, connecting the transmission to the differential in rear-wheel-drive vehicles. U-joints enable the driveshaft to move up and down while maintaining a constant rotational speed, compensating for the changing angles between the transmission and the rear axle. This ensures a smooth transfer of power and helps prevent damage to other drivetrain components.

Types of U-Joints

There are several types of U-joints, including single Cardan, double Cardan, and constant velocity (CV) joints. Single Cardan joints are the most common, consisting of a cross-shaped piece with needle bearings at each end. Double Cardan joints, also known as Hooke’s joints, are essentially two single Cardan joints combined, providing greater flexibility and reducing vibration. CV joints are used in front-wheel-drive vehicles, allowing for a wider range of motion while maintaining a constant velocity. Each type of U-joint has its own unique characteristics and applications, making it essential to choose the right one for your vehicle.

Maintenance and Inspection of U-Joints

Regular maintenance and inspection of U-joints are essential to prevent premature wear and potential failure. When inspecting U-joints, look for signs of wear, such as rust or corrosion, loose or damaged needle bearings, or excessive play in the joint. Applying the appropriate grease for U-joints during routine maintenance can significantly extend their lifespan and ensure smooth operation. It’s important to consult your vehicle’s owner’s manual for specific lubrication intervals and recommended grease types. In addition, always inspect U-joints when performing other maintenance tasks, such as oil changes or tire rotations, to identify potential issues early.

Common U-Joint Issues and Troubleshooting

Some common issues associated with U-joints include excessive vibration, clunking noises, and difficulty turning. These issues can be caused by a variety of factors, such as worn or damaged needle bearings, lack of lubrication, or misaligned components. If you suspect a problem with your U-joints, inspect them for visible damage and ensure they are properly lubricated. In some cases, replacing the U-joint may be necessary to resolve the issue. It’s also essential to address any underlying issues that may have contributed to U-joint failure, such as worn suspension components or an improperly balanced driveshaft.

Replacing a Faulty U-Joint

If you determine that your U-joint is damaged and requires replacement, it’s important to follow the appropriate steps to ensure a safe and effective repair. First, consult your vehicle’s service manual for specific procedures and torque specifications. Before beginning the replacement process, make sure you have the necessary tools, such as a socket set, torque wrench, and snap ring pliers. Additionally, you may need a U-joint press or a bench vise to remove the old U-joint and install the new one. When installing the new U-joint, ensure that it is properly aligned and seated, and apply the recommended grease for U-joints to ensure optimal performance and longevity.

Preventive Measures and Best Practices for U-Joint Maintenance

To minimize the risk of U-joint failure and extend their lifespan, follow these best practices:

- Regularly inspect U-joints for signs of wear, corrosion, or damage.

- Lubricate U-joints at the intervals recommended in your vehicle’s owner’s manual, using the appropriate grease for U-joints.

- Address any drivetrain or suspension issues that may contribute to U-joint wear or failure, such as misaligned components, worn bushings, or an improperly balanced driveshaft.

- Practice good driving habits, such as avoiding sudden acceleration or sharp turns, which can put excessive stress on U-joints and other drivetrain components.

- If you’re not comfortable performing U-joint maintenance or replacement yourself, seek the help of a qualified mechanic to ensure a safe and proper repair.

Conclusion

In conclusion, U-joints play a vital role in a vehicle’s drivetrain, ensuring smooth and efficient power transfer from the engine to the wheels. Regular maintenance, including the proper application of grease for U-joints, can help prevent premature wear and prolong their lifespan. By understanding the function of U-joints, inspecting them regularly, and addressing any issues promptly, you can ensure a safe and comfortable driving experience. Furthermore, following preventive measures and best practices for U-joint maintenance can help minimize the risk of failure and keep your vehicle running smoothly for years to come.